-

Services

ServicesCNC Machining ServiceDie casting serviceSheet Metal FabricationSurface service

CNC Machining Guide

Here we summarize a lot of various processing problems encountered in the CNC machining process, you can learn a lot of machining skills about part forming here

Related LinksNew!

GD&T For Injection Molding

We've added GD&T to our in-house first article inspections (FAIs) and process capability studies to give you an even more complete set of dimensional verification options.

Related LinksSurface treatment skills

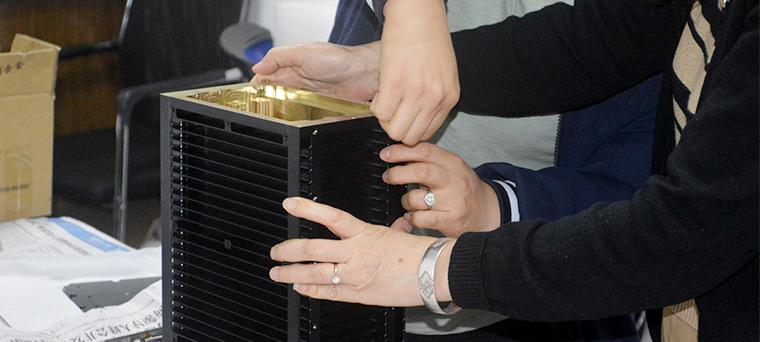

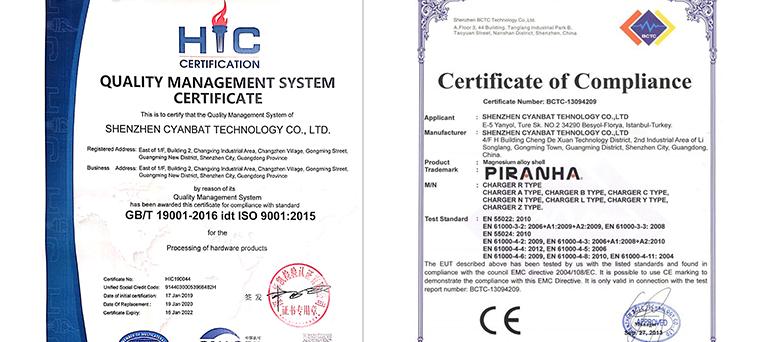

Researched the surface treatment process of magnesium alloy products, including the salt spray test and adhesion research on the surface, mainly to make the product more adaptable to the environment

Related LinksSheet metal precision points

To ensure the accuracy of processing, both from the operator and from the processing method. Only in this way can ensure the final processing quality and effect.

-

Materials

You can provide, I will make

We show only part of the material, if you need other types of material machining, you can directly contact our person in charge

-

Resources

Technology Precipitation

We outline over a decade of machining experience in magnesium alloy cnc machining, die casting, and various skills and techniques -

About Us

About Us

Contact Us

Cyanbat technology co., ltd.

Shenzhen Guangming District

Changxing Technology Garden

Postal Code: 518132

call:+86 18194014169

E: cyanbat88@gmail.comBest-in-Class Online Quoting

CYANBAT is a manufacturer of prototypes of products for the military, aviation, and marine industries, and is a one-stop manufacturing enterprise